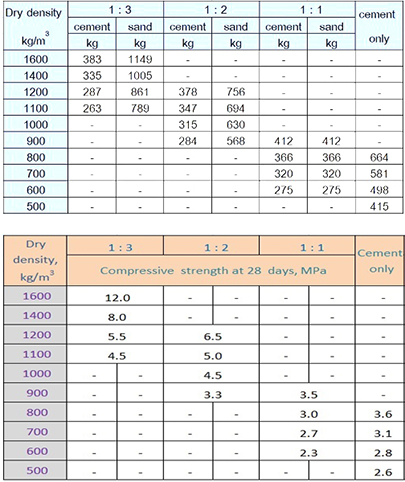

With the aim of obtaining the accurate measurement of any construction site the usage of this user friendly concrete mix design spreadsheet is absolutely necessary.

Foam concrete mix design calculator.

The mix design weights and volumes will now be proportioned on the right side of the grid.

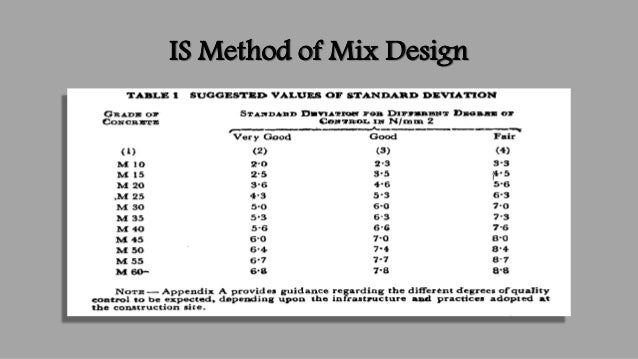

Where s standard deviation in n mm 2 4 as per table 1 of is 10262 2009.

Water 191 6 kg m 3.

For trial 1 of concrete in lab to check its properties.

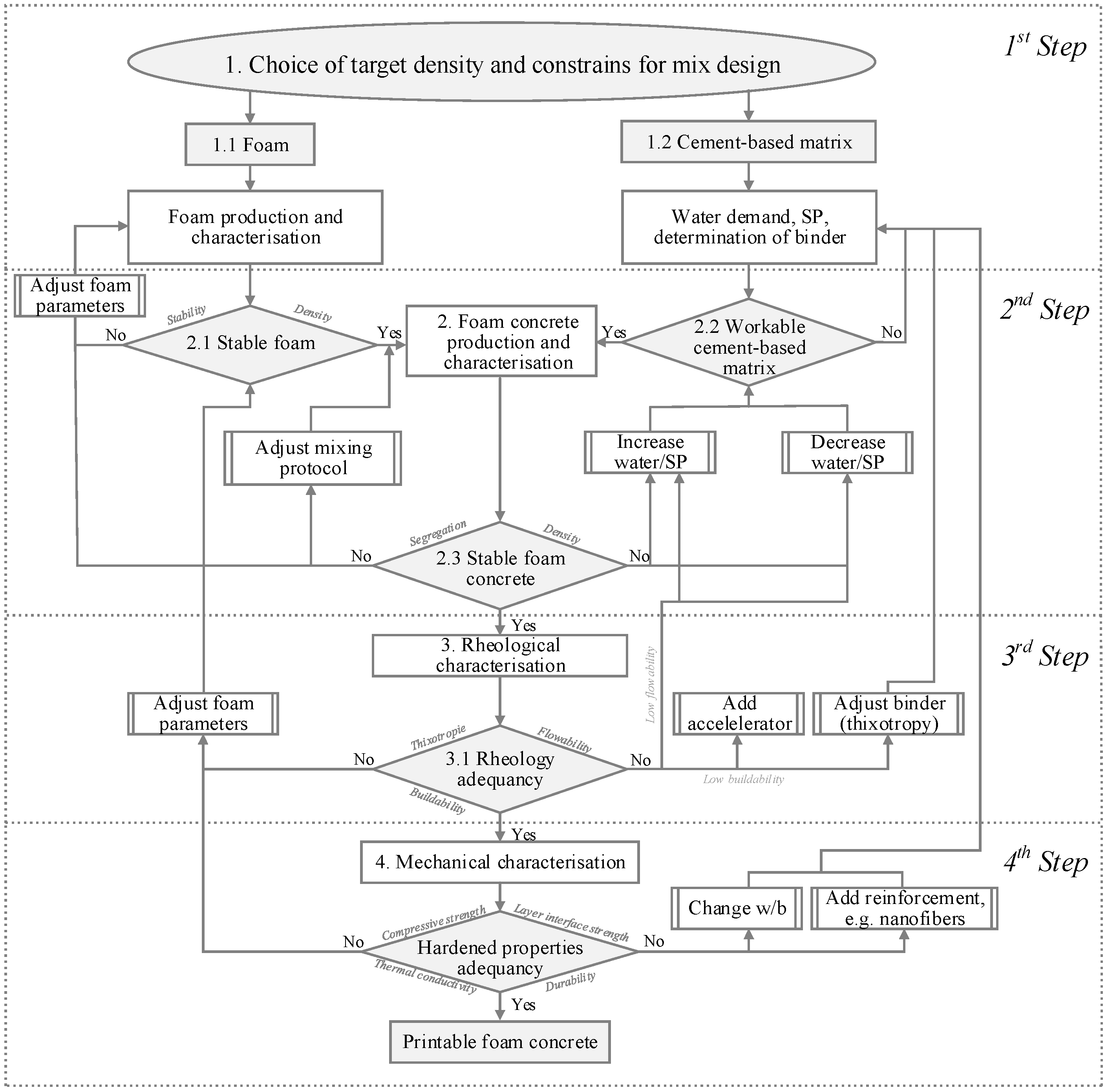

There is at present no guidance or standard method for proportioning foamed concrete because the hardened density of foamed concrete depends on the saturation level in its pores.

It will help you save time and hassle when creating mix designs and doing cost scenario analysis.

Astm c 796 97 provides a method of calculation of foam.

Density of foam concrete 400 600 800 1000 1200 1400 1600 fly ash 90 275 450 520 730 900 990 cement 300 270 290 310 320 320 340 water for concrete mix 110 110 120 120 140 150 160 water for foam 40 36 32 28 23 19 15 amount of foam liter 800 715 630 560 460 370 290 amount of foam agent greenfroth kg 1 0 9 0 8 0 7 0 58 0 48 0 38 the weight of.

It will satisfy durability economy.

Fine aggregates 800 94 kg m 3.

Proportional mix design foamed concrete are also discussed.

Cement 383 2 kg m 3.

F target f ck 1 65 x s 25 1 65 x 4 0 31 6 n mm 2.

Mix design calculator download our free mix design calculator for cellular concrete.

Coarse aggregate 1087 75 kg m 3.

As in normal concretes the greater the air content the weaker the material so with foamed concrete densities ranging from 200kg m3 to 1900kg m3 it is not surprising that the lower densities produce the lower strengths and at present even the densities at the upper limits do not produce strengths much above 15n mm2.

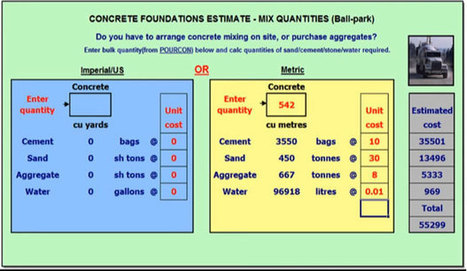

A very basic cellular concrete mix design would consist simply of portland cement water and externally generated foam which is also referred to sometimes as preformed foam.

If you wish to calculate yield or trial batches please fill in the actual density and trial batch size ft3 cells.

Procedure for concrete mix design of m25 concrete step 1 determination of target strength.

Concrete mix proportions for concrete trial mix 1.

Himsworth constant for 5 risk factor is 1 65.

In this case standard deviation is taken from is 456 against m 20 is 4 0.

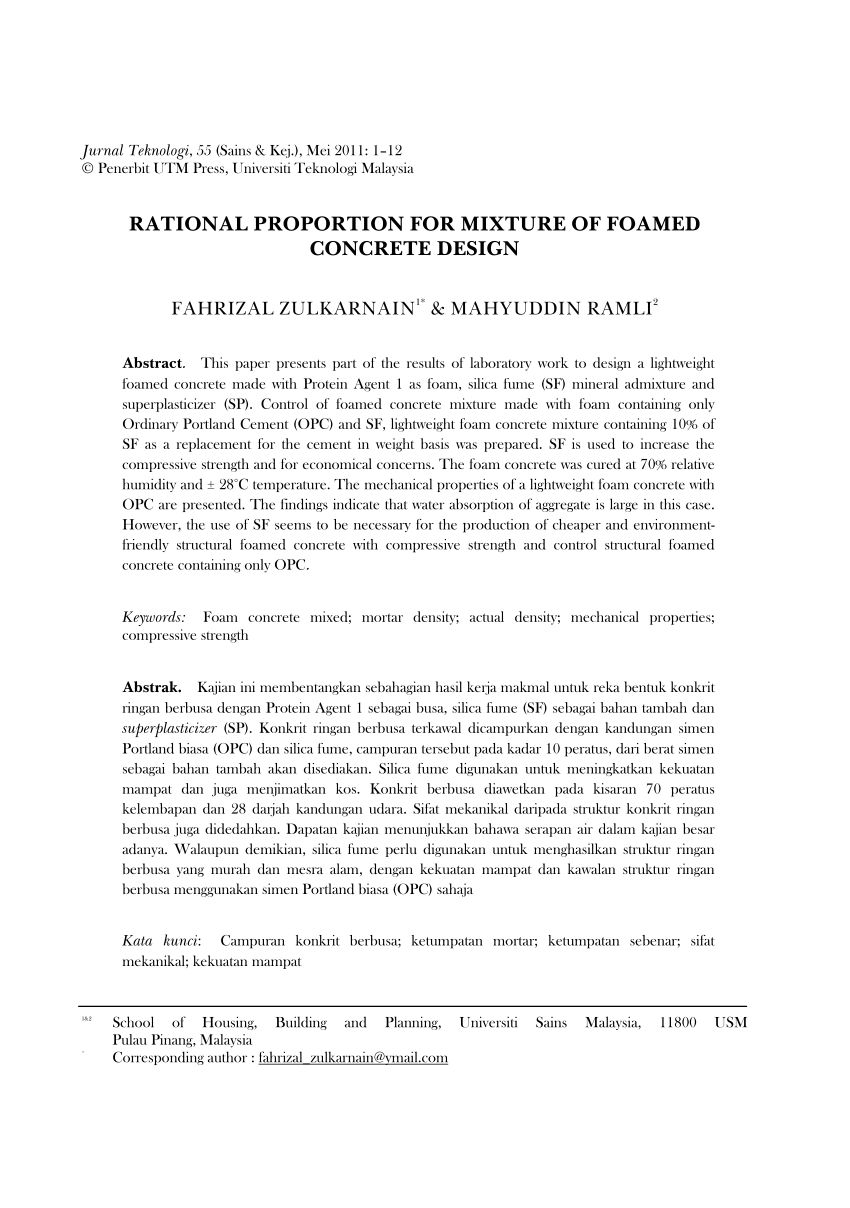

Sample mix proportions of foamed concrete are given in table 1 2 3.