Due to their size they are more difficult to store as an alternative support for road handling.

How to make floor jack go down.

Inspect the jack stand to make sure they are located properly or inspect the ground area to make sure there are no obstacles before lowering a vehicle.

It consists of two heavy steel pipes one inside the other.

Become a wranglerstar memb.

Do you have a hydraulic jack that is slow doesn t stay up or maybe doesn t lift at all.

Step 3 say clear loudly as a safety double check in alerting others that you are now going to lower the vehicle.

The oil level should be between 3 16 to a 1 4 of an inch above the cylinder on most floor jack models.

How can you tell if your floor jack has air in the system.

A screw jack is a metal support post that can be adjusted to level the floor.

Let s look at how to properly bleed a hydraulic floor jack.

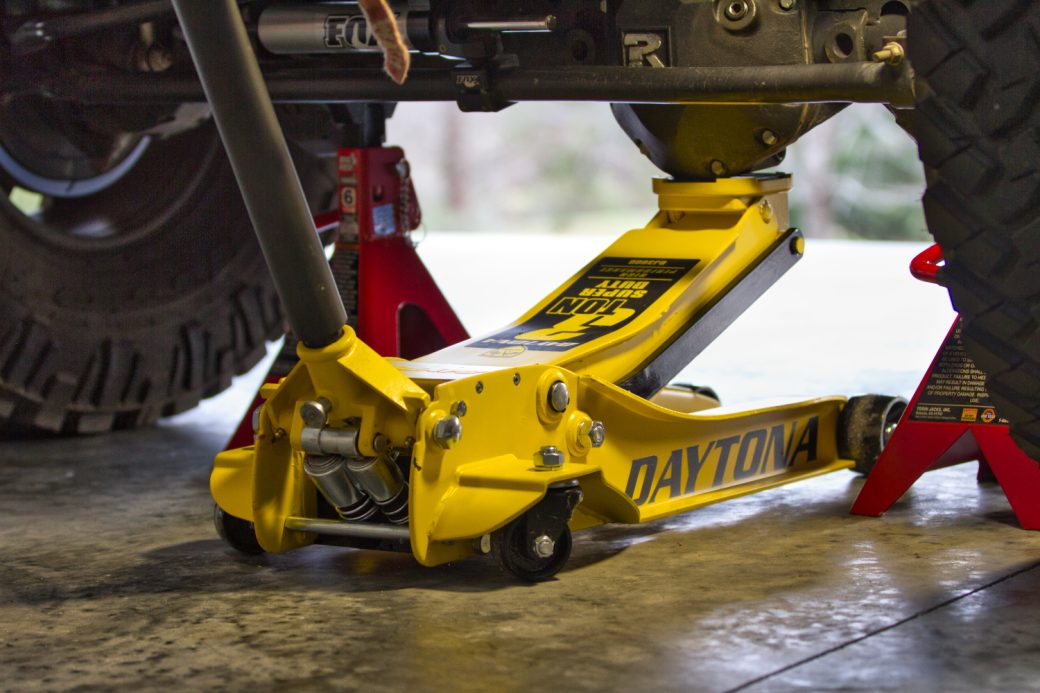

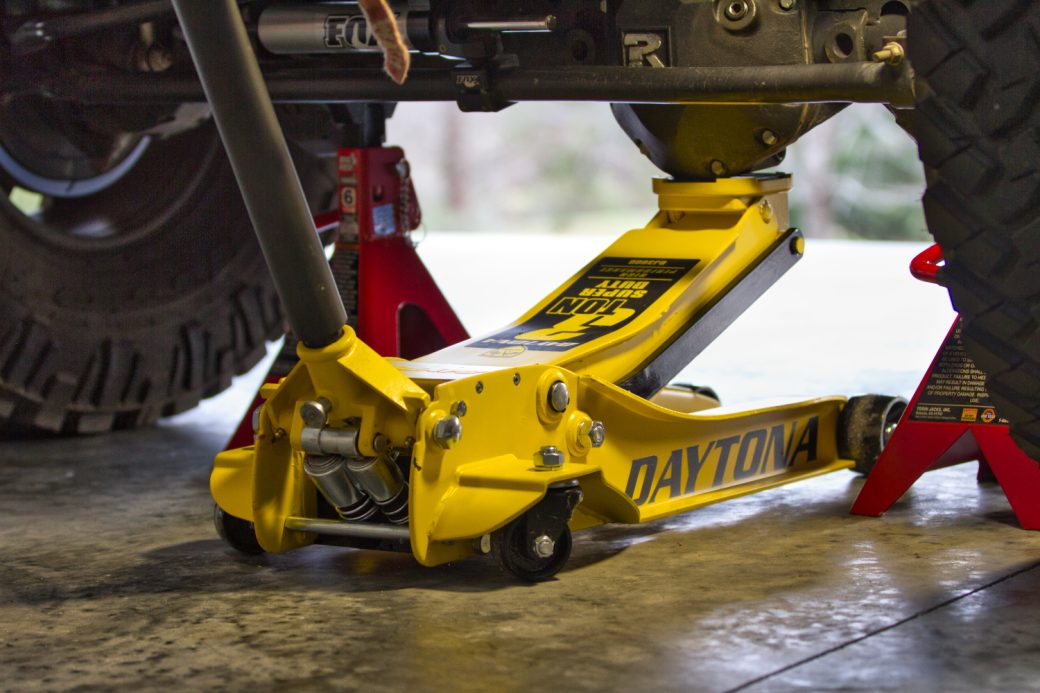

Floor jacks are more reliable easier to use and provide more stability than other types of jack.

Use only a quality grade hydraulic floor jack oil do not use regular oil products.

The floor jacks are made of light metal used for small cars while those made of steel are more powerful and work with large cars.

The screw jack is attached with nails to the underside of the girder and to the wood block atop a concrete pier.

How to fix a floor jack that won t life.

Bleeding air from a floor jack is requ.

Remove the oil fill plug and look into the chamber.

I m trying to change a tire with the only equipment i have a hydraulic jack and i can t figure out how to make it go back down.

The inside pipe is threaded and adjusted up and down by turning a large wing nut.

How do you make a hydraulic jack go back down.

Refer to the owner s manual of your floor jack to ensure the level and measurement is correct.